In-depth Analysis

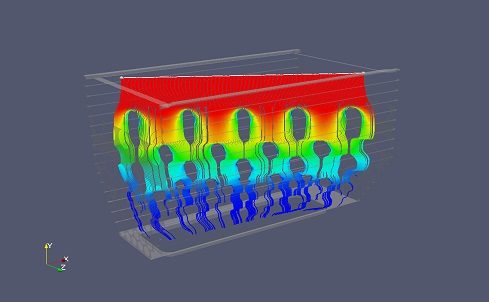

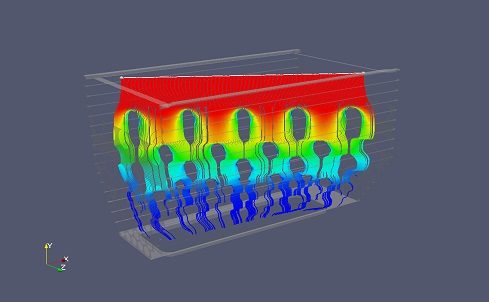

Water temperature distribution profiles and the chemical composition of the exhaust gases in the heat exchanger are optimised.

ELCO invests heavily in research and development to ensure that the proven stainless steel heat exchangers continue to offer the best efficiency, superior reliability and excellent lifetime performance.

In-depth Analysis

Water temperature distribution profiles and the chemical composition of the exhaust gases in the heat exchanger are optimised.

Efficient heat transfer

Specially designed hydraulic chambers ensure that the water turbulence delivers maximum heat transfer with the lowest possible pressure drop

Ultimate Efficiency

Thanks to their high condensation rate, gas condensing boilers from ELCO achieve the A and A+ ratings of the ErP classification, even at full load

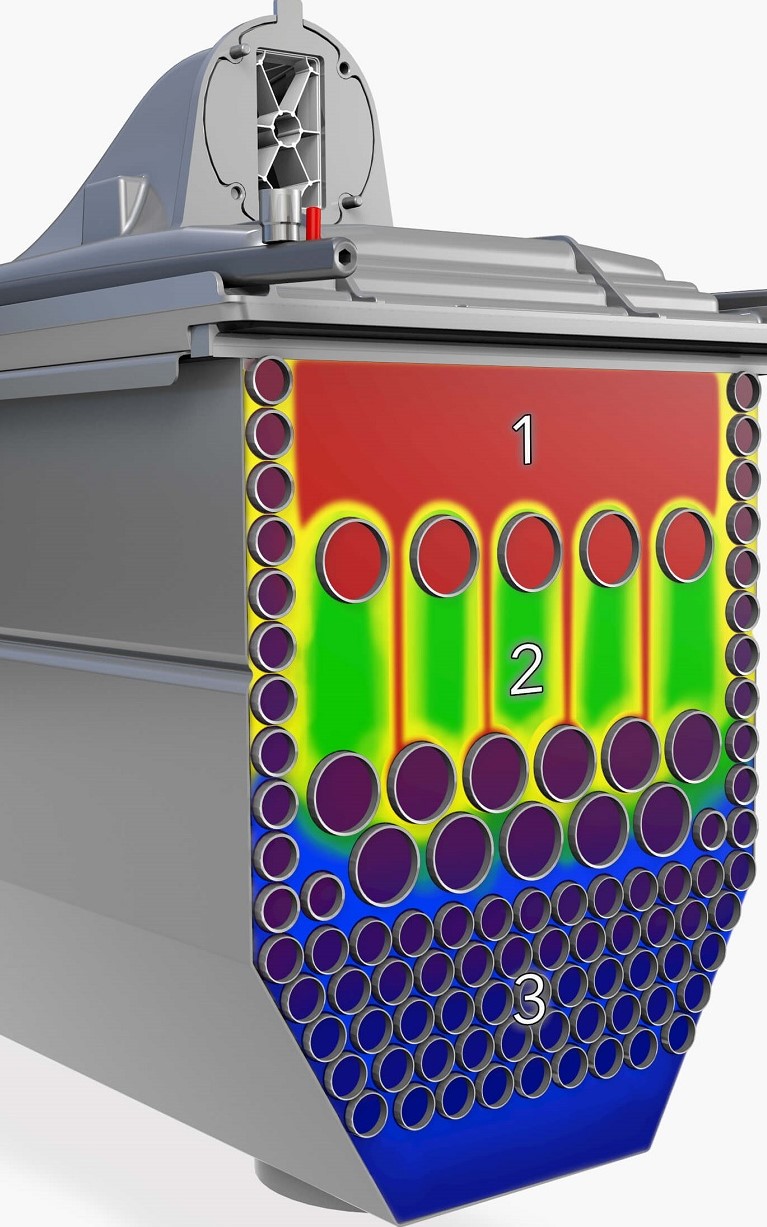

By managing specific zones with conflicting requirements, maximum energy yield can be achieved with extremely low emissions. In zone 1, the temperatures rise to over 1,000 °C, the formation of NOx is hardly possible here. Thanks to a fast flow and rapid temperature reduction, the flue gas temperatures are kept above 600 °C, which enables optimal CO formation. The condensation and the transfer of the remaining flue gas energy take place at approx. 56 °C in zone 3.

ELCO uses the same burner and heat exchanger technology across the entire premium boiler range from 2.0 kW to 2 MW.

From the largest commercial units to our premium range of domestic boilers, all ELCO products are designed to significantly reduce NOx emissions. ELCO products are 60% below the EU limit for NOx emissions.

Do you have any questions or comments?

You can find other contact details here: